Many organizations routinely send out hundreds of thousands — or more — documents to their clients and customers. These documents (which can include statements, bills, invoices, sales and marketing material, and correspondence) are issued by a variety of enterprises from many vertical markets. In addition, digital technology has added another dimension to the term “sending out” documents. It no longer refers only to printed and mailed hard copy, but to documents and/or notifications transmitted via email, websites, smartphones, and other devices.

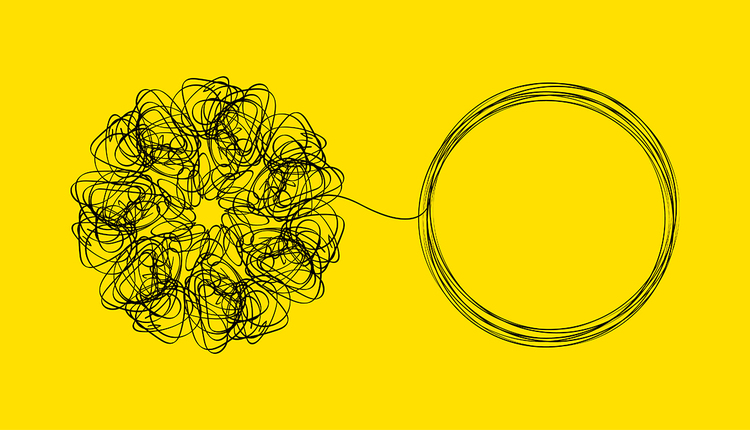

While the digital revolution has made it possible to compose, print, insert, re-print/resend (when necessary), and sort this high volume of documents in a single production run, the overall process is made up of several steps that have the potential for breakdowns in accuracy, efficiency, and cost-effectiveness. The challenge is how to combine these steps, which often involve different hardware and software, into a smooth workflow to ensure that all pages are printed properly and they go to the correct recipient through the preferred channel in a timely manner. This is no small task. However, identifying the potential gaps in the production process and installing measures to prevent them is a key step in ensuring a seamless workflow. Here are five of the top gaps we all can relate to:

Gap #1 — Composition Composition of documents is typically done upstream before a job reaches the printer. However, composition can be key to accurately tracking and monitoring the whole production process if, for example, barcodes or other types of coding are used to match the pages of a document. Yet, in many cases, the people who compose the documents have little to no understanding or capability for using barcodes or other identifying markers.

Gap #2 — Document Information For many printing operations — both in-house departments and third-party service providers — the print file arrives with few if any indicators about what’s inside, such as: How many pages? How many pages per envelope? How many documents for electronic versus print distribution? Where a page count is provided, this is the only information the printer has available to track and monitor the job as a whole.

Gap #3 — Accuracy After the pages are printed, they move to insertion, and many printers rely on this stage to confirm the accuracy of the printing. This requires simple arithmetic: We have 10,000 total pages in the file; 9,000 are for mailing and 1,000 are for electronic distribution. Do we have 9,000 inserted envelopes? Do we have 1,000 documents ready for electronic transmission? Not only should an accurate count be maintained, but ensuring that the correct documents are inserted into the right envelopes must also be verified, ideally through a cost-effective process. If this is all happening, great. If not, what’s missing, and how do we reconcile any discrepancies and guarantee document integrity?

Gap #4 — Exceptions Reprints can include pages skipped or damaged in prior production steps, and now they also can include those intended for electronic delivery that bounce back when the recipient has changed their email or SMS text address. Damaged hard copy is, of course, usually easy to identify and can be reprinted on the spot. Bounce-backs need to be discovered as quickly as possible and, as a last resort, printed and mailed. This is often done manually and can mean lost time in getting the document to the recipient.

Gap #5 — Delivery Sorting for delivery is generally done either in-house or by an outside service provider. This step is where the USPS becomes involved in the process, both in the use of the USPS-provided barcodes that direct a piece of mail to the correct address and/or by the USPS providing some quality assurance when a job arrives at one of its service centers.

Installing Stop-Gap Measures

Starting upstream, many organizations have found it useful to invite document designers to at least tour the production floor to gain a realistic understanding of how the production process works, as well as what is and is not possible in a high-volume, high-speed print production environment. Appropriate design is very effective in preventing problems as the job is produced.

Still, perhaps the most common problem through the printing stage is missing pages, and the method used most often to track pages occurs at the insertion stage, when the number of documents is reconciled with the number of envelopes plus the number of documents tagged for electronic distribution. As mentioned earlier, some production operations may use barcodes on the pages to identify and track them, but this requires investing in technology to read the barcodes. While this can seem like a costly proposition upfront, it may return the investment in improved efficiency and reduced waste of time and materials.

Regarding reprints, a closed loop process works best. In this process, when a page or a document is damaged as it’s inserted, it’s ejected and immediately goes back into the print queue for reprinting and inserting. Additionally, it’s advisable to keep the documents that are marked for electronic delivery in the print queue, but with the actual print step suppressed. That way, if electronic delivery fails and the email bounces back, the document can be printed and mailed with little delay.

At the sorting phase, and circling back upstream, the mailing list has hopefully been purged of items returned earlier as undeliverable to save the wasted time and expense of mailing to non-existent or wrong addresses, and the USPS’s IMb barcodes have been accurately applied.

Finding a Holistic Approach

Perhaps the most effective option is to fully automate the workflow with software that can track and monitor the job as it moves through all the stages of production. Currently, several types and brands of these solutions are available to suit the needs of specific production environments. Some of these solutions may work only on certain steps of the production process and/or may be proprietary to the brand of hardware in use.

Other, more sophisticated workflow solutions provide a dashboard that gives production personnel visibility into the status of the print job throughout the entire process, as well as providing options for moving or redirecting certain functions as the job runs. Managers should examine their specific environments to decide which types of solutions would work best for them.

While digital technologies have made it possible to deliver all types of communications to a greater number of recipients — and faster than ever before — the new processes come with challenges of their own, chiefly upholding a standard of accuracy throughout the various steps in the overall production process. The number of communication channels currently available and customer expectations and preferences for these channels only add to the task.

What’s required is a holistic view of the various steps in production, with providers looking both upstream and downstream for solutions that can contribute to the quality of the print run as a whole. Production managers and personnel should already be familiar with common ways to keep the work flowing smoothly, but in dealing with high-speed, high-volume production runs, the most effective way to ensure accuracy and solve the problems of today’s automation may just be adding a little more automation.

An electronic document industry pioneer, Ernie Crawford is President/CEO and founder of Crawford Technologies, based in Toronto, ON. One of only a small number people worldwide with M-EDP (Master Electronic Document Professional) designation, Ernie has more than 30 years of senior marketing and management experience in the high-volume electronic printing market.

Click here to return to the Document production and printing topic page.