I've been in the direct mail business since the late eighties. I've personally put the wrong postage on envelopes and had employees do the same. I've also seen the wrong product go out with the wrong list of names. And I've been in the midst of production nightmares only to have other customers calling to find out the status of their jobs, while we're trying to fix machines and frantically get the last job out the door and off the dock. I've done jobs quickly only to have them sit at the post office because the client didn't have enough money in the permit account.

The pressure, the competition, the frequently changing postal regulations, customer disappointments, changing deadlines, being at the mercy of people who have no mercy; this is my world. And if you're reading this magazine, it may be your world, too.

An Idea Is Born

One day while I watched my wife hand write form after form for the day, I was struck at the repetitiveness of it all. She had to write out the daily production sheets, upcoming jobs, note what product was in the warehouse and what product we were still waiting on. That's when I had this vision that someday we'd track all mail jobs with a barcode. Barcoding everything would allow us to track product in the building, upcoming jobs and help with applying the right list and the correct postage to the right job. That's when I began dreaming about a new software program that could relieve pressure, help manage jobs, ensure that jobs conform to most postal regulations, automatically keep customers informed about the status of their jobs and generate machine capacity reports. After about four years of programming and testing, I launched it in my own business. It's called Mailstar Production Tracking System.

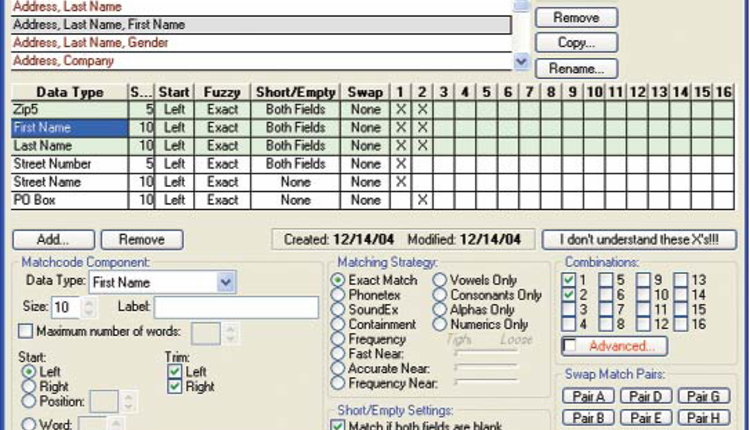

How It Works

With this software, when a customer calls to initiate a job, a service rep simply clicks a single button on the computer screen, then taps a letter that corresponds to the client's name. This automatically fills in a new job ticket. The screen then prompts the service rep to ask questions like: when do they want to mail, when will product arrive, when will the list of names arrive, what's the size of the mailing, how will it be mailed, what to do with overages and whether there are any special instructions to pay attention to. This saves redundant questions and aggravation for the customer and the service rep. It also relieves the mail house of tremendous communication headaches. Plus, it's all automatic.

Once that information is entered into the system, there's no room for miscommunication between staff and customers or customer service and production. Postal regulations are embedded to help make sure no one puts the wrong postal payment method on a piece. Each step that needs to be verified for quality control is verified, or the software won't let the job advance. With no handwritten notes to be misread or misconstrued, jobs go more smoothly, without reprints or screw-ups.

Keeping Customers Informed

The number one feature of this software is the way it keeps customers informed every step of the way. Customers receive an automatically generated email when their products arrive at the dock. They receive another email after the mail house has determined the number of addresses being processed, what the total and average postage cost per unit will be and whether the amount in the client's post office permit account is enough. If it isn't, the client gets a forewarning so this doesn't compromise the mailing deadline.

When the job is finished, the software sends a final email telling the customer how many pieces were processed, postage cost, leftover count and when it's intended to mail. Customers know the job status at every step. They don't have to call, and staff doesn't have to scramble to find an answer. Customers frequently give feedback on how much they like this aspect of the software. One of our customers told us, "In the old days, my boss would ask me the status every other day, I'd call you and you'd have to get back to me. Nowadays, I simply forward to my boss the emails that let me know exactly where the job is at. You've removed a lot of angst from the process. Thank you."

In addition to simplifying job entry and processing, the software's Production Tracking System also creates machine capacity reports. These reports show setup time, run time, average pieces per hour, cost per job, average time per job, average pieces per job and percentage of capacity usage per machine based on one shift.

I used to think my inkjet ran at 75% to 80% capacity. But now, management reports show me we averaged 45.6% for the year. That gave me the insight for what we could really do. No one could have convinced me it was that low.

How Easy Is It to Implement?

Mailstar is button-driven and very intuitive. It doesn't use pull-down menus that require hunting to find the function. It's all right there on the screen. The idea is to make it simple for an operator to click a button and complete an entire task. For instance, if a customer asks for the overages to be shipped back to them, clicking one button fills out the shipping ticket and labels for the boxes. Some people have been able to use Mailstar without even being trained. However, training does come standard with the software.

I think that the administrative portion is very adaptable and quickly learned. Production may find it cumbersome at first; they'll have to learn the reasons for scanning the barcode for starting and stopping jobs. However, their function is only a matter of seconds for every job. So it doesn't waste valuable operator time to produce the reports showing equipment usage and setup times.

Personally, now that our own business has had the benefit of using this software for three years, none of us would ever go back. My wife tells me that if I took it away, she'd quit. Because it's always been a nightmare to keep track of all the things that this software keeps track of for us. And yet, some of what it does would be impossible for staff to track, like when equipment starts and stops. We now book more work based on the machine's true capacity, not what I think it is. At a minimum, it saves the work of one full-time employee, possibly two. At the same time, it can multiply the effectiveness of everyone else on staff.

Ron and Cathy Labrozzi started Mailstar, Inc. in 1989. To find out more about Mailstar, email Sales@Mailstarinc.com.