Is the goal to reduce processing costs or mandate the use of envelopes? They're the same thing. As postal engineers see it, the best way to minimize processing costs would be to mandate the use of envelopes in the letter mail stream. If mandating envelopes isn't possible, then booklets and self mailers need to be sealed on at least three sides, preferably four. The affects on mail preparation, marketing effectiveness, mail owner costs, and ultimately mail volumes are not a concern of the engineers or the operations group responsible for sorting letter mail.

If you want to know what an acceptable mail stream looks like to these two postal groups, read the New Standards for Letter-Size Booklets and Folded Self-Mailers published by the USPS in the Federal Register in December, 2008. The scariest part of this document was in the introduction which stated "we [have] identified incremental opportunities for improvement" This statement to the mailing industry is an unambiguous notice that more incremental changes are planned.

Changes to the definition of direct mail products, tabbing requirements, paper weights, coefficient of friction (intended to control the coatings we use), static charge, perforated and non perforated tabs, dimensional changes, future changes to cards, along with the exclusion of non paper materials as attachments, inserts or used in mail piece construction, were developed by postal engineers without performing in-depth testing on self-mailer designs. The proposed new standards are the wish list of postal employees who clearly do not understand the dynamics of the industry they serve.

And now postal management has put together an informal MTAC work group to coordinate joint testing of folded self mailers. With joint testing of mail piece designs, industry leaders plan to work with the USPS towards achieving an equitable balance between efficient processing, mail piece production costs, and the marketing effectiveness of the letter sized mailstream.

For the Postal Service, I believe joint testing is a ploy, a means to justify implementation of the proposed rules published in December. With these divergent goals and lack of good faith, the industry test pieces will certainly underperform postal expectations, based on testing criteria established by the engineers. The goal of our associations and the mailing professionals involved in this round of testing should be to block postal employees from destroying letter mail volumes.

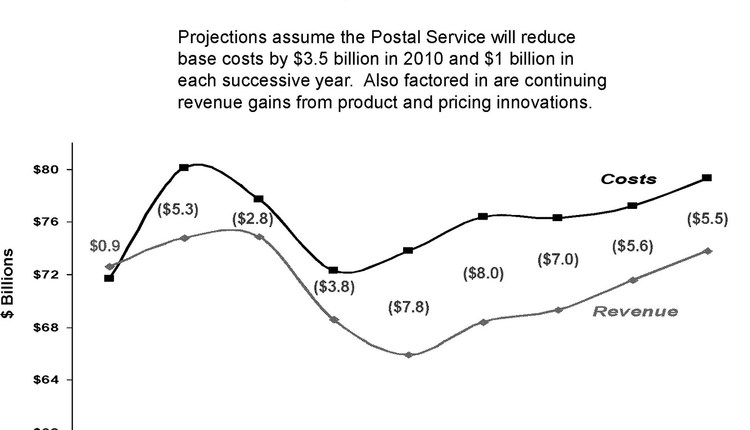

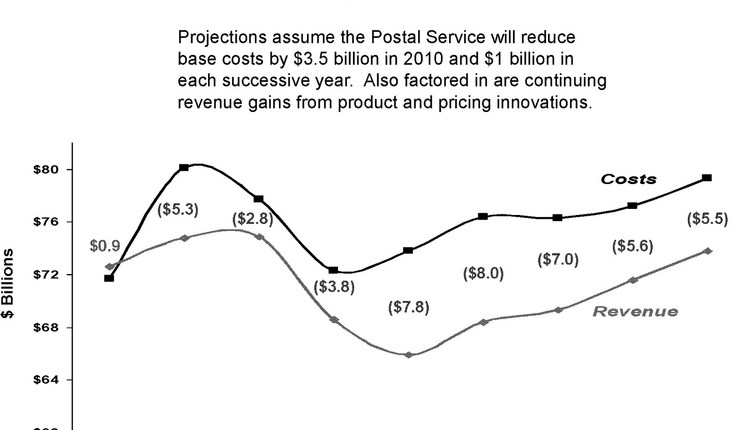

The postal imperative to redesign the letter mailstream is not supported by current financial facts and could do irreparable harm to the Postal Service and the industry it serves!

The Annual Compliance Report (submitted by the USPS to the PRC) provides financial information as to the costs and operating margins generated by the existing letter mailstream. It also brings a stark perspective of what the Postal Service risks if changes have a negative affect on mail owners.

According to the Annual Compliance Report for 2008, letter mail totaled 150 billion pieces. This means that of the 200 billion pieces of mail classified as market-dominant products, letters represented 75% of the volume. Looking at the costing and revenue data, letters delivered 77% of the USPS operating margin or $20 billion of the 26 billion dollars generated by market-dominant mail.

On a per piece basis, Standard Mail letters cost $0.096 each to collect, transport to sortation equipment (DBCS machines), process on the machines (4 runs of approx 5 seconds per run), transport to delivery units and deliver to consumers. The Postal Service says that this activity generates a revenue stream of $0.185 for each piece mailed or $0.089 in margin. First Class letters cost $0.11 and generate $0.328 in revenue returning $0.218 per piece in margin.

How much cost does postal management believe they can remove from this extremely profitable mailstream, by increasing the efficiency of a mechanical process taking less than 20 seconds to complete?

Remember that changes proposed in the Federal Register dealt with only one aspect of letter mail processing that begins with the collection or verification of mail and ends with delivery to consumers. The proposed redesign of the letter mail stream and the new MTAC testing, will only impact mechanical sortation by the DBCS machines. No proposed changes (current or future) would affect or reduce the substantial costs associated with the collection, verification, transportation or delivery of letter mail!

The direct mail industry should make sure that any changes deemed necessary by postal employees, answer the basic question of what cost savings there will be to the USPS if the industry agrees to make recommended changes. As an example, how much will the total cost of letter mail processing be reduced if the USPS redefines a folded self mailer to be a single sheet of paper? How much will reducing the height of a self mailer by an eighth of an inch save the Postal Service? The industry must insist that the Postal Service prove that an eighth of an inch in height negatively affects the sortation costs of self mailers, while having no affect on the sortation costs of enveloped mail!

The information the direct mail industry must provide to the Postal Service in this joint effort is: how mail preparation costs will be impacted by proposed changes. Industry and postal participants must then compare the projected savings (if any) generated from more efficient DBCS processing to the increased costs of preparation. The Postal Service believes that tabbing on the lead and trail edges of a self mailer is more efficient for their machines, even though past postal testing proved no difference in jam rates between two tabs on top and tabs in the lead/trail position. Any possible savings from changing tab placement must be objectively evaluated against the costs incurred by the mailing industry in making proposed changes.

The fact that the industry has resoundingly said it can not efficiently produce mail with a lead/trail edge tab configuration has had no affect on postal management. Oh we get testing (before they implement their new standards) but the incredible lack of concern or understanding by postal employees of the processes and equipment customers use to prepare mail is astounding.

Any savings achieved in more efficient processing has to balance the additional costs of preparation. For changing the tab placement, these costs include extensive equipment purchases and a reduction in industry processing speeds by as much as 60%. Any costs not covered by a reduction in postage will be paid by mail owners, who are at the tipping point of abandoning direct mail for alternative marketing!

Finally, our industry must calculate the affect a more efficient letter mailstream will have on the perceived marketing value direct mail has for mail owners. In achieving processing perfection, will self mailers end up having less marketing appeal than a #10 envelope? The proposed rules required three 1½ inch tabs on two folded sheets of paper with a final size of 3½ x 5 inches. Three inches of paper tabs on the lead edge (3½ inches high) and an inch and a half white tab on the trail edge may not be a product mail owners are willing to utilize in their marketing campaigns.

Would mail owners switch to other designs having a lower tab to product ratio such as envelopes? Or would changes in design and construction be perceived as a reduction in the marketing value of mail? What is the financial break even for the Postal Service where savings gained from improved DBCS processing are out weighed by a corresponding loss in volume of the most profitable mail the Postal Service handles?

As the industry moves ahead with joint testing of letter sized mail we have to make sure, that in a rush to minimize processing costs, we don't allow the Postal Service to drive its cash cow into extinction and destroy what's left of our industry. If changes are made to the letter sized mailstream that negatively impacts mail volume, the Postal Service will never recover. Postal management proved by the release of the Federal Register in December that they are not concerned about the financial consequences of their actions. Obviously, it is up to the direct mail industry to insist that sound financial decisions are made as the engineers push testing to justify the unilateral implementation of their reforms.

The Postal Service has never made the connection between their policies, customer reaction to those policies and mail volume. Even at this time of massive volume decreases, they were unconcerned with the affects the proposed DMM changes would have on the volume of mail and its accompanying decline in revenue. The USPS promotes the fantasy that they are operating as a real business but management has never evaluated the financial consequences of their actions.

Tinkering with mail piece designs that may alter the marketing appeal of the letter mailstream is dangerous; a major redesign is called a disaster. Standard Mail in January had a 22% decline in volume (SPLY). What does the drive for increasing efficiencies in DBCS sortation look like? Might it be a 50% permanent reduction in mail volume? With the margins letter mail currently generates, at what level of perfection must self mailers process to be deemed acceptable by postal management? And at what cost?

Todd Butler of Butler Mailing Services can be reached at 513-870-5060, toddb@butlermail.com or www.ekemailer.com.

If you want to know what an acceptable mail stream looks like to these two postal groups, read the New Standards for Letter-Size Booklets and Folded Self-Mailers published by the USPS in the Federal Register in December, 2008. The scariest part of this document was in the introduction which stated "we [have] identified incremental opportunities for improvement" This statement to the mailing industry is an unambiguous notice that more incremental changes are planned.

Changes to the definition of direct mail products, tabbing requirements, paper weights, coefficient of friction (intended to control the coatings we use), static charge, perforated and non perforated tabs, dimensional changes, future changes to cards, along with the exclusion of non paper materials as attachments, inserts or used in mail piece construction, were developed by postal engineers without performing in-depth testing on self-mailer designs. The proposed new standards are the wish list of postal employees who clearly do not understand the dynamics of the industry they serve.

And now postal management has put together an informal MTAC work group to coordinate joint testing of folded self mailers. With joint testing of mail piece designs, industry leaders plan to work with the USPS towards achieving an equitable balance between efficient processing, mail piece production costs, and the marketing effectiveness of the letter sized mailstream.

For the Postal Service, I believe joint testing is a ploy, a means to justify implementation of the proposed rules published in December. With these divergent goals and lack of good faith, the industry test pieces will certainly underperform postal expectations, based on testing criteria established by the engineers. The goal of our associations and the mailing professionals involved in this round of testing should be to block postal employees from destroying letter mail volumes.

The postal imperative to redesign the letter mailstream is not supported by current financial facts and could do irreparable harm to the Postal Service and the industry it serves!

The Annual Compliance Report (submitted by the USPS to the PRC) provides financial information as to the costs and operating margins generated by the existing letter mailstream. It also brings a stark perspective of what the Postal Service risks if changes have a negative affect on mail owners.

According to the Annual Compliance Report for 2008, letter mail totaled 150 billion pieces. This means that of the 200 billion pieces of mail classified as market-dominant products, letters represented 75% of the volume. Looking at the costing and revenue data, letters delivered 77% of the USPS operating margin or $20 billion of the 26 billion dollars generated by market-dominant mail.

On a per piece basis, Standard Mail letters cost $0.096 each to collect, transport to sortation equipment (DBCS machines), process on the machines (4 runs of approx 5 seconds per run), transport to delivery units and deliver to consumers. The Postal Service says that this activity generates a revenue stream of $0.185 for each piece mailed or $0.089 in margin. First Class letters cost $0.11 and generate $0.328 in revenue returning $0.218 per piece in margin.

How much cost does postal management believe they can remove from this extremely profitable mailstream, by increasing the efficiency of a mechanical process taking less than 20 seconds to complete?

Remember that changes proposed in the Federal Register dealt with only one aspect of letter mail processing that begins with the collection or verification of mail and ends with delivery to consumers. The proposed redesign of the letter mail stream and the new MTAC testing, will only impact mechanical sortation by the DBCS machines. No proposed changes (current or future) would affect or reduce the substantial costs associated with the collection, verification, transportation or delivery of letter mail!

The direct mail industry should make sure that any changes deemed necessary by postal employees, answer the basic question of what cost savings there will be to the USPS if the industry agrees to make recommended changes. As an example, how much will the total cost of letter mail processing be reduced if the USPS redefines a folded self mailer to be a single sheet of paper? How much will reducing the height of a self mailer by an eighth of an inch save the Postal Service? The industry must insist that the Postal Service prove that an eighth of an inch in height negatively affects the sortation costs of self mailers, while having no affect on the sortation costs of enveloped mail!

The information the direct mail industry must provide to the Postal Service in this joint effort is: how mail preparation costs will be impacted by proposed changes. Industry and postal participants must then compare the projected savings (if any) generated from more efficient DBCS processing to the increased costs of preparation. The Postal Service believes that tabbing on the lead and trail edges of a self mailer is more efficient for their machines, even though past postal testing proved no difference in jam rates between two tabs on top and tabs in the lead/trail position. Any possible savings from changing tab placement must be objectively evaluated against the costs incurred by the mailing industry in making proposed changes.

The fact that the industry has resoundingly said it can not efficiently produce mail with a lead/trail edge tab configuration has had no affect on postal management. Oh we get testing (before they implement their new standards) but the incredible lack of concern or understanding by postal employees of the processes and equipment customers use to prepare mail is astounding.

Any savings achieved in more efficient processing has to balance the additional costs of preparation. For changing the tab placement, these costs include extensive equipment purchases and a reduction in industry processing speeds by as much as 60%. Any costs not covered by a reduction in postage will be paid by mail owners, who are at the tipping point of abandoning direct mail for alternative marketing!

Finally, our industry must calculate the affect a more efficient letter mailstream will have on the perceived marketing value direct mail has for mail owners. In achieving processing perfection, will self mailers end up having less marketing appeal than a #10 envelope? The proposed rules required three 1½ inch tabs on two folded sheets of paper with a final size of 3½ x 5 inches. Three inches of paper tabs on the lead edge (3½ inches high) and an inch and a half white tab on the trail edge may not be a product mail owners are willing to utilize in their marketing campaigns.

Would mail owners switch to other designs having a lower tab to product ratio such as envelopes? Or would changes in design and construction be perceived as a reduction in the marketing value of mail? What is the financial break even for the Postal Service where savings gained from improved DBCS processing are out weighed by a corresponding loss in volume of the most profitable mail the Postal Service handles?

As the industry moves ahead with joint testing of letter sized mail we have to make sure, that in a rush to minimize processing costs, we don't allow the Postal Service to drive its cash cow into extinction and destroy what's left of our industry. If changes are made to the letter sized mailstream that negatively impacts mail volume, the Postal Service will never recover. Postal management proved by the release of the Federal Register in December that they are not concerned about the financial consequences of their actions. Obviously, it is up to the direct mail industry to insist that sound financial decisions are made as the engineers push testing to justify the unilateral implementation of their reforms.

The Postal Service has never made the connection between their policies, customer reaction to those policies and mail volume. Even at this time of massive volume decreases, they were unconcerned with the affects the proposed DMM changes would have on the volume of mail and its accompanying decline in revenue. The USPS promotes the fantasy that they are operating as a real business but management has never evaluated the financial consequences of their actions.

Tinkering with mail piece designs that may alter the marketing appeal of the letter mailstream is dangerous; a major redesign is called a disaster. Standard Mail in January had a 22% decline in volume (SPLY). What does the drive for increasing efficiencies in DBCS sortation look like? Might it be a 50% permanent reduction in mail volume? With the margins letter mail currently generates, at what level of perfection must self mailers process to be deemed acceptable by postal management? And at what cost?

Todd Butler of Butler Mailing Services can be reached at 513-870-5060, toddb@butlermail.com or www.ekemailer.com.