This article originally appeared in the July/August, 2018 issue of Mailing Systems Technology.

Everyone has one claim to fame in life. Mine is that I am the (self-proclaimed) top expert on mailing systems in the United States. I have not been able to tell anyone about this until now because there was never the right time or place. You try to bring this up to someone at a party, and they suddenly need to “use the restroom.” Luckily for me, if you are reading this article, it is because you are actually interested in mailing equipment or are looking to replace a system that is no longer serving your needs.

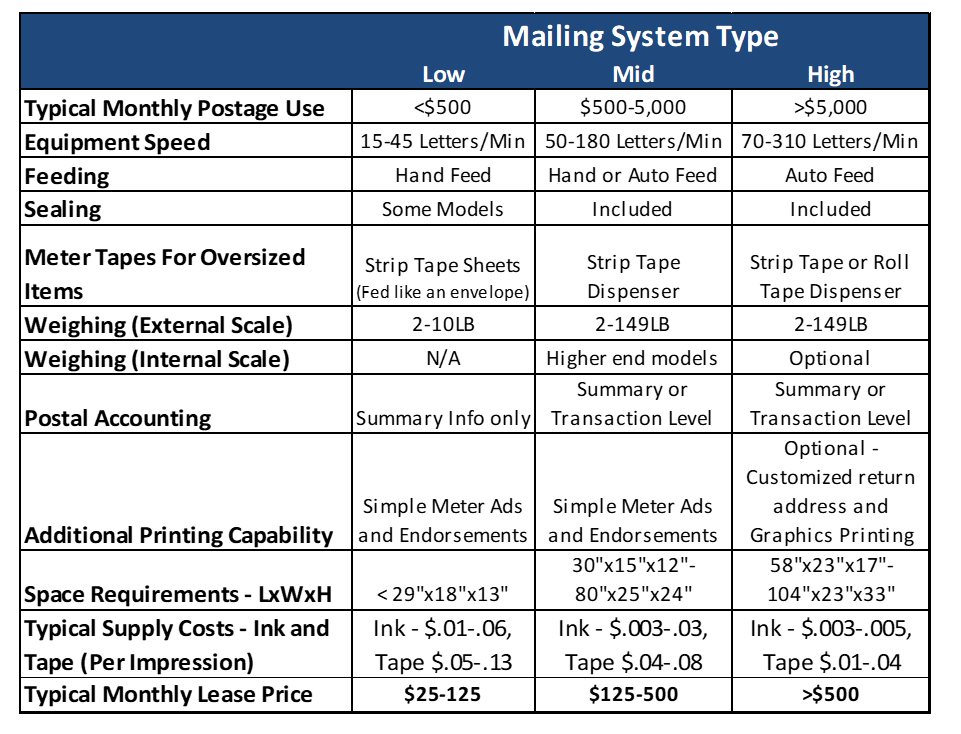

But what to look for when embarking on this venture? The questions to ask when attempting to select the right mailing system for your organization can seem overwhelming. Here are the 10 core questions that should go into your decision for the optimal system.

1. Recommended Mail Volumes

What type of system do you need based on your current and projected mail volumes?

Mailing equipment is designed for specific usage levels. This is important for three reasons:

- Service - The performance of the unit could decrease if the machine is used far above these recommended volumes.

- Over-buying - If your volumes are much lower than those recommended, you could be paying more for a machine than you need.

- Productivity – All units are designed to process a specific mail volume efficiently. If volumes are too high, it may not be productive to tie up labor with a slower system. If volumes are too low, the unit may be too complex for the needs of the application.

*It is important to note that the recommended mail volumes and descriptions on this table are defined by Postal Advocate Inc. and not by the manufacturers.

2. Machine Speed

How fast do you need the system to process the mail to make it efficient?

This is the manufacturer’s rated speed of the unit and shows how many envelopes can be processed in one minute. No one runs a machine at the manufacturer’s rated speed except professional operators who are constantly feeding the same size material without needing to start and stop. You should expect speeds of 25-50% less. This is the biggest differentiator between systems and creates the largest cost increases.

3. Envelope Feeding and Stacking

How do you need the mail fed into and out of the system?

The way the machine feeds mail into the unit is one of the most important aspects because it determines the level of equipment and its ease of use.

- Hand Feed: Push in and pull out – Most basic low-volume units have a speed range of 15-25 per minute.

- Hand Feed - Push from the left and the machine feeds it through the unit These low- to mid-volume units have a speed range of 25-65 per minute.

- Automatic Feed - This means that you can put a pile of mail onto the stacker and the machine will pull them into the unit. These units are much easier and faster that hand feed units and are designed to process higher volumes. The differentiator of automatic feed systems is how they work. Lower volume units will require the operator to use side guides to set the mail, whereas high-volume units will have automatic alignment. Automatic alignment is especially helpful when you have an internal scale system because it lets you run different size and weight letters and flats together. Most mid- and high-volume automatic feed systems have this option.

- Drop Stacker – This is the most common exit option for low- to mid-volume applications.

- Power Stacker – This is an exit option for high-volume applications. These stackers typically have a conveyor and a pressure wheel (to improve sealing) and can hold up to 500 finished mail pieces before needing to be emptied.

4. Envelope Sealing

Do I need the system to seal envelopes, and how are they to be prepared prior to processing?

It is very time-consuming to seal envelopes manually, not to mention your tongue can get sore. I have heard (but cannot verify) that each envelope can provide up to 17 calories as well. All mailing systems in the mid- and high-volume category will have sealing come standard, and it is an option on many in the low-volume category.

The main question with sealing systems is how the mail needs to be prepared prior to being sealed. This is especially important with automatic feed systems that process large quantities.

- Flaps Closed Sealing - The flaps are down just like they came in the box of envelopes. The system will open the piece slightly and run it under its brush/sponge to wet the piece. Because it is trying to seal every piece, it is important to check that you do not have envelopes that are already sealed because they could rip or get jammed. Pieces sealed prior to processing should be run together with the sealer turned off.

- Flaps Open Sealing - Flaps open means that the envelope flaps are stacked on top of each other. This option is only available with high-volume automatic feed machines and is becoming much less popular. The benefit of this type of sealing system is you can run sealed and unsealed mail together.

- Flaps Open and Closed Sealing - Some high-volume automatic feed mailing systems can seal envelopes with the flaps open or closed. This offers great flexibility for companies with different types of mail coming down from multiple departments.

5. Meter Tapes

Are there many pieces that are too big to fit into the system and will require meter tapes?

There are frequent times when you will need to run mail or packages that are too thick to fit into the machine. All vendors provide meter tapes that can be run through the unit. As a rule of thumb, the bigger the unit, the less expensive the tapes become because they are bought in higher quantities.

- Strip Tape Sheets – Low-volume mailing systems will use tape sheets that are run through the machine like an envelope. These tape sheets have two to four places to print postage. These tapes are self-adhesive and easy to apply. Cost per tape (per imprint): $.05-.13

- Strip Tape Dispenser - Most mid-volume (and some high-volume) units will have a separate tape dispenser where they can be created at the touch of a button. These tapes come two to a strip that is perforated in the middle and can be rerun again on the other side. Strip tapes are self-adhesive and easy to apply. Cost per tape (per imprint): $.06-.08

- Roll Tape - Many mid/high-volume automatic feed mailing systems will have a roll tape dispenser that will cut the tapes to the proper size. This is easier than needing to load tape strips into a dispenser and rerun the back sides to maximize their use. Self-adhesive cost per tape (per imprint): $.02-.04. Some high-volume units will have an option for gummed back tape that comes out wet, and the cost per tape is about $.01.

The newest trend in mailing systems is to have a software connected to the unit that can process 4x6 inch shipping labels (instead of meter tapes) that include the destination and return address as well as the postage and a tracking barcode. This can save two to a whopping 56% on postage and can provide an easier way to track your mail. This tool can be in many forms, including being directly on the main control panel or a software that sits next to the unit.

6. Weighing

How are you going to weigh and rate different sized pieces?

Most mailing systems have a scale that is connected in some way. They make it easy to calculate the right amount of postage and will have most USPS rates.

- 2-10 LB External Scale - These are the most common scale sizes. Many are built right onto the mailing system for space savings and simplicity.

- 15-149 LB External Scale - These are for entities that have some package weighing requirements. These scale sizes can add considerable expense, and we recommend that you see if the extra capacity justifies the cost. Most items over 10 pounds are typically going through private carriers, and third-party external scales can be purchased for much lower costs.

- Optional Internal Scale - This is a great option for entities that do a lot of mixed weight mail. The different size and weight pieces can be placed on the feeder and the unit will pull them in, assess their size (to determine if they are a letter or flat), weigh, rate, seal, and meter the piece in one operation. This is much faster and more accurate than weighing and rating each piece. This option is available on many automatic feed mailing systems.

Do you need to track mail by department or cost center?

Many entities need to track their postage expense so it can be charged back to departments or cost centers. This means they need to know how much each group is spending so they can bill them back later. Here are specific accounting questions:

- How many accounts do you need to track?

- Are you only looking for a month-end summary, or do you need the details of every transaction?

- How do you need to access the data? Some options include:

o From the screen of the mailing system or printed on a meter tape

o With a connected printer

o Having the machine connected to a PC or laptop

o From a USB drive that can be taken from the unit and placed into your computer

o Accessed from the vendor’s website

8. Additional Printing CapabilityWhat else would I like the system to print?

Mailing systems have been able to do basic advertisement plates and inscriptions as long as I have been in the industry. The difference now is that with modern inkjet printing and new color capabilities, there is a lot more that can be printed at a much higher quality to help promote your message. It used to be that to customize any print, you needed to order plates or download from the vendor. Now higher end systems will allow you to create content and download it to your unit without the vendor charges and delays. Here are the typical items that can be printed:

- Meter advertisement

- Postal inscription

- Return address

- QR code or custom graphic

9. Space Requirements

Can the system fit in my space?

When deciding on a mailing system, it is imperative to check your space requirements prior to ordering.

10. Investment/Price

What is the total amount you will pay?

I left this one for last because there are several items you need to look at regarding the price of the unit.

- Buy, Lease, or Rent? – Most entities will lease their mailing equipment because all of the services are included in one payment. I typically recommend this for low- and mid-volume units, but high-volume should consider both options. For low-volume units, renting (which is similar to the lease structure) is also an option, but it is for shorter term commitments.

- What is included? Make sure to know the pricing on the following and if these options are included on the lease:

o Equipment

o Meter rental

o Meter resets

o Postage advances

o Maintenance

o Scale rate changes

- What is the cost of supplies? This is typically meter ink and tape but could also include printhead replacement.

- What are the added fees and terms? You should look at the cost for late charges, finance fees, loyalty plans, and vendor replacement insurance because these costs can add up if you are not paying attention to them.

- What happens at the end of the agreement? Many leases have automatic evergreen clauses that extend the agreement for an additional 12 months if you do not provide notice by a specific period. See if these can be changed or set up a reminder on your calendar for the future. There could also be pickup fees or lease termination fees you want to understand.

Adam Lewenberg, CMDSS, MDC, President of Postal Advocate Inc., runs the largest Mail Audit and Recovery firm in the United States and Canada. They manage the biggest mail equipment fleet in the world and their mission is to help organizations with multi-locations reduce mail related expenses, recover lost postage funds, and simplify visibility and oversight. Since 2013, they have helped their clients save an average of 60% and over $38 million on equipment, avoidable fees, and lost postage. He can be reached at 617.372.6853 or adam.lewenberg@postaladvocate.com