The BB1000 process workflow begins with the new ease-of-use envelope converting technology of the W+D Easy Enveloper to create engaging, haptic, windowed, foiled envelopes and also some specialty shape cut USPS TED-C shapes from digital preprint. The BB1000 produces real envelope mail packages - NOT A WRAP. As the preprinted web is being converted in the enveloping section of the BB1000, it then securely “envelopes-on-the-fly” the inside content material using inserting technologies from the W+D BB700 and W+D BB820 direct mail inserter designs. These W+D inserters are renowned for size and product range flexibility, inserting intelligence and high-net production outputs. The completed envelope package from the BB1000 is a mail piece ready for induction directly into the USPS mail stream.

The two-step modular workflow of first preprinting 1:1 envelope outers and inside content into rolls. Then real envelope finishing + inserting with the W+D BB1000 allows maximum production flexibility and the industry’s fastest time to market total system solution for a powerful 1:1 matched envelope letter package. Now you can also have both the front and backside of the envelope personalized as well as other haptic finishing in a single pass workflow. Additionally, some of these haptic finishes qualify for the 4% postage discount under the 2022 USPS mailing discount promotional program.

· The BB1000 is available in two versions: a 6½ x 11½” version rated at up to 20,000 per/hour and a 9 x 12” multi format capable version rated at up to 16, 000 per/hour. Both versions will run smaller sizes down to a #9 and even to a true A7 (5-1/4 x 7-1/4) with 2 3/8” flap and 1” throat.

· Can run envelopes with single or multiple windows or closed face.

· Window patcher can also be used for foil enhancement of the envelope.

· Can also be used to manufacture ONLY unfilled envelopes which then can be sealed in a

secondary inserting process.

· Can produce a variety of hard to insert sizes: a true A7 (5-1/4” x 7-1/4”) with a 2-3/8” square flap and 1” throat with 5 x 7 card; 6 x 9 booklet with a #9 BRE or 8-7/8” CRE.

· Offers additional paper saving with very tight 3/16” insert clearance tolerance.

· Can do micro comingling by zip code for each envelope.

· 3 personalization configuration options: gathering section only, cut-sheet channel, or roll inputs.

· Upper elevated track can be added for personalization of reply envelopes or premiums.

· 6-station or 8-station feeder base that is upgradeable up to 24 feeders based on model.

· Wide range of quick-change feeder types.

· Envelope format: Minimum #9, A6,A7 - Maximum 6.5”x11.5” - Can also be configured

to handle 9”x 12” flats.

Andrew Schipke W+D North America Vice President Marketing and Strategic Sales cites that “The power of the envelope is real in the world of direct mail. Marketers are looking for new ways to leverage data and be able to deliver secure and complete personalized messaging. No longer is high print quality 1:1 direct mail only relegated toa postcard or a self-mailer. W+D now takes the proven effectiveness and superior marketing performance of a real envelope mail package to a new level. Now data driven 1:1 personalization on both sides of the envelope and haptic enhanced envelopes to engage recipients as soon as they touch the physical mail piece will increase the all-important customer experience mail moment. The BB1000 is complete envelope finishing + inserting solution for any commercial printer with an inkjet press that is looking to leverage their printer assets and now compete in this growing direct mail segment. “

Click here to see a short preview video of the revolutionary BB1000 process for preprint inkjet

For more information and more detailed BB1000 video and to get 1:1 envelope mail package samples produced from the BB1000 contact W+D North America at (913) 227-3018 or email at info@wdnorthamerica.com

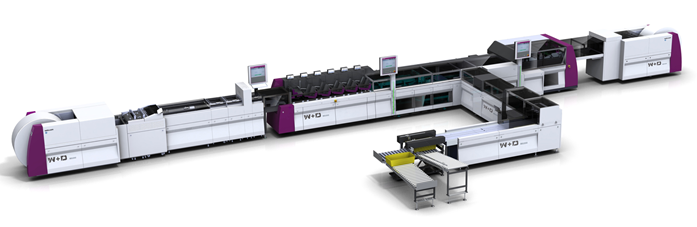

Photo : New W+D BB1000 envelope finishing +inserting system for personalized direct mail print

ABOUT WINKLER+DÜNNEBIER GMBH

Winkler+Dünnebier GmbH (W+D) offers a wide range of highly efficient, integrated system solutions for the mail and postal industry, as well as for the tissue and hygiene industry. With more than 100 years of industry-shaping innovations, W+D has core competence in the converting and processing of thin and in-homogeneous materials—such as paper, tissue and nonwovens—at high speeds and tight tolerances. With our innovative and tailor-made system solutions and services, W+D focuses on the entire internal value chain for their customers. Part of the Barry-Wehmiller family, W+D has production and distribution sites in Germany, Malaysia and the United States, with sales and service support around the world. For more information, go to www.wdnorthamerica.com

ABOUT BARRY-WEHMILLER

Barry-Wehmiller is a diversified global supplier of engineering consulting and manufacturing technology for the packaging, corrugating, sheeting and paper converting industries. By blending people-centric leadership with disciplined operational strategies and purpose-driven growth, Barry-Wehmiller has become a $2 billion organization with 11,000-plus team members united by a common belief: to use the power of business to build a better world. To see how, go to barry-wehmiller.com.