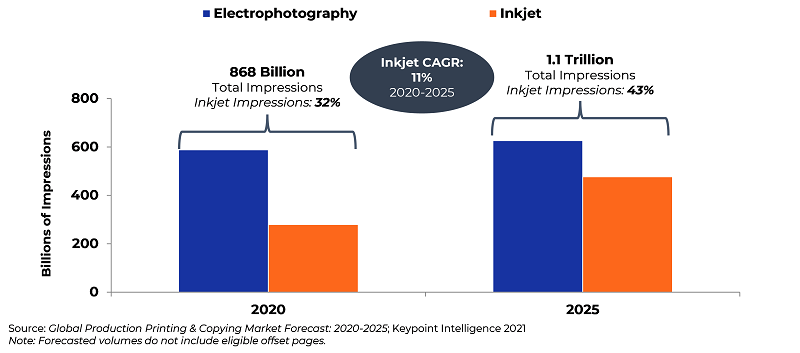

Inkjet technology has become increasingly popular in the recent past, and this is hardly surprising. Its value proposition aligns well with the communication needs of today’s consumers and buyers. As a result, the volume of pages being transferred from offset and digital toner devices to inkjet is healthy and growing. Keypoint Intelligence’s Global Production Printing & Copying Market Forecast predicts a strong growth rate for inkjet through 2025.

Figure 1: Electrophotographic vs. Inkjet Impressions

Recognizing the opportunity and need, technology providers have been steadily improving their product portfolios and capabilities. Moreover, new players continue to enter the market with the forecasted growth in the adoption of inkjet solutions.

Suppose you are seeking a print provider that offers inkjet or considering investing in an inkjet press yourself. In either case, you’ll quickly notice that there is no shortage of information about the various technologies and capabilities. What’s more, the information available to today’s buyers is growing all the time. So much information can make the decision-making process quite overwhelming, and the consequences can be costly if the wrong decision is made. Due to variances in technology, ink, paper, and other factors, it is nearly impossible for a linear decision-making process to reveal the right solution. As a result, selecting the best inkjet production press for your operation isn’t always as simple as evaluating speed, capacity, and quality. Today’s print operations have a great many choices when it comes to inkjet, but this piece attempts to make sense of them.

The Incongruity of Inkjet

Modern inkjet devices are available in all shapes and sizes. In fact, at the date of this publication there are upwards of 70 different models that qualify as production inkjet presses. These presses can use coated or uncoated stock, and include continuous paper or cut-sheet feeding systems. Ink choices include water-based pigment or dye inks as well as UV-curable or solvent inks. Depending on the ink type that is chosen, additional paper considerations play a key role. For example, papers can be pre-treated or primed to improve press performance and image quality, or coatings can be applied post-printing. The two primary types of printheads that are used to apply ink to paper are piezo and thermal, and both have their own unique advantages. Capacity, or the maximum number of prints that a device can print in a month, is also a key consideration. All of these characteristics are important when it comes to identifying the best inkjet press for your print operation.

But wait, there’s more! Adding in the variables of service requirements, available uptime, environmental control investments, image quality, the digital front end, speed, finishing, and the cost of the initial investment can quickly disarm even the most decisive buying committee. So how do you determine the best solution for your business? Before we answer that question, let’s explore just a few of the variables in the technologies mentioned above. Their descriptions highlight why it’s important to fully understand all your options before coming to a decision.

• Coated Paper: A special coating is applied that enables the paper to absorb ink without smudging or bleeding.

• Uncoated Paper: Available in a variety of textures, uncoated paper takes less time to dry and meets the requirements for many of today’s inkjet-eligible applications.

• Continuous Feed (CF): This technology is excellent for specific applications and workflows. Books, transactional documents, and direct mail run well on CF devices. The process is cost efficient and highly productive.

• Cut Sheet Fed: Offers flexibility in matching substrates to a variety of applications, making it easier to expand into new applications that weren’t originally specified for inkjet.

• Water-Based Pigment Inks: These inks consist of dry powder suspended in water pigment that sits on top of the paper rather than being absorbed. They tend to keep their vibrancy longer as they resist fading.

• Water-Based Dye Inks: Composed of dissolved dye suspended in a liquid and designed to be absorbed into the paper instead of sitting on top of it. These inks are known for brilliant colors and their likeliness to color match images and texts more accurately.

• Hybrid ink: Often developed by an equipment manufacturer or partner to complement other components of their technology, hybrid ink is not defined by a single ink category.

• UV-Curable Ink: This ink eliminates the need for pre-coated paper. Ultraviolet technology is quick to dry, highly durable, and sticks to most materials. It is also very economical. Printing is clean and clear, does not smudge, and will not fade over time. UV ink is known to be environmentally friendly at 99.5% VOC (Volatile Organic Chemical) free.

• Solvent Ink: Durable and suitable for printing on a wide variety of substrates, these inks are well-suited for outdoor signage or applications that need to last a long time.

• Thermal Printheads: Offering a cost advantage over piezo, thermal technology uses heat to release the ink from the printhead. Two different droplet sizes are available.

• Piezoelectric Printhead: Although piezoelectric printheads are a bit more expensive than thermal, they can be used with a wider range of inks, solvents, pigments, and dyes. Droplet sizes can vary to form detailed images.

The considerations listed above are only some of the factors associated with inkjet technology. Forming a decision without a thorough understanding of the technology is the equivalent of a crap shoot. The good news is that making the right decision doesn’t need to be as daunting as it seems.

Start with a Strategy

The Ben Franklin decision-making approach—which is essentially compiling a list of the pros and cons, thinking about them, and then coming to a decision—can work well in many cases. When it comes to inkjet, though, this approach will only be as good as the information that is gathered to support your strategy and goals. To be clear, having a desire to increase productivity with a faster press is not a strategy. Striving to offer the best print quality is not a strategy. Purchasing the latest technologies is not a strategy. Strategy is a detailed plan that outlines the specific actions required to achieve a goal. In our industry, strategy is often influenced by communication trends and best practices.

When developing an inkjet strategy, consider your current customers' communication needs rather than immediately deciding on printheads and substate capabilities. Think about the shifts that are occurring in their world. What changes would you need to make to better support their vision?

• Start by breaking it down based on the applications they depend on. Think about the following:

o Do they include personalized or versioned content?

o Are their volumes growing or declining?

o What is the ideal substrate for each application? What is acceptable, and what’s not?

o Are there things you can’t produce that your competitors can? Why?

o How are your customers using print to create better customer experiences?

o What is the required turnaround time, and is it increasing or declining?

o How do you finish the application? Why?

o What are the quality expectations?

o What applications would benefit from adding more color?

• Determine the workflow that you currently use to support these applications, then ask yourself:

o Will an inkjet press require a different workflow to keep up with speed and capacity?

o What sheet size is optimal for the applications you’ve identified?

o What tools are currently required to maintain color consistency and control? Will the technology you’re considering change or improve that?

o Where can you add artificial intelligence (AI) or more automation to your workflow?

• Assess the following finishing considerations:

o Do you intend to use your current offline finishing devices?

o What sheet size limitations need to be noted?

o Do specific applications benefit from inline finishing?

This list of questions is only a start and is certainly not intended to be all-inclusive. Once you’ve recorded the mechanics of current and future work requirements, determine if an inkjet press will complement or replace current printing presses. By answering these questions ahead of time, you can narrow your search because the options you don’t need to consider will naturally be ruled out.

Other opportunities to narrow the focus involve gathering print samples from different inkjet technologies. Make sure these samples are generated from your own files to help you gain a very visual and useful comparison. Next, share the print samples with your current and potential clients because their feedback is key to a quick start with inkjet. Naturally, there are several other factors that must be addressed before a decision can be made. The key takeaway is that it’s impossible to make a compelling case (e.g., thermal inkjet printheads are a better solution than piezo, an advantage exists in the ability to use coated vs. non coated paper) without first understanding all the characteristics of the application.

The Bottom Line

As time goes on, technological advancements will only accelerate, and various capabilities will continue to blend. This might simplify the process for identifying the right inkjet press for your organization, but it might also make the process even more complicated. Either way, try to eliminate words like “best” from your vernacular when evaluating your options, because the answer will often depend on a variety of factors. Inkjet technology opens the door to many new opportunities, and it’s about identifying the right fit for your specific applications and needs.

Karen Kimerer of Keypoint Intelligence has experienced the many challenges of expanding current market opportunities and securing new business. She has developed a systematic approach to these opportunities, addressing the unique requirements of becoming a leader in our changing industry. She is well-versed in 1:1 marketing, web-to-print, direct mail, book publishing, supply chain management, data segmentation, channel integration, and photo products.

This article originally appeared in the July/August, 2022 issue of Mailing Systems Technology.