It’s easy to forget how much a damaged piece of mail can cost a business producing transactional mail.

Time, resources, and trust are all affected every time a pair of hands touches a single regulated document. And don’t forget that a few dollars are added to your processing costs each time.

Hard to believe?

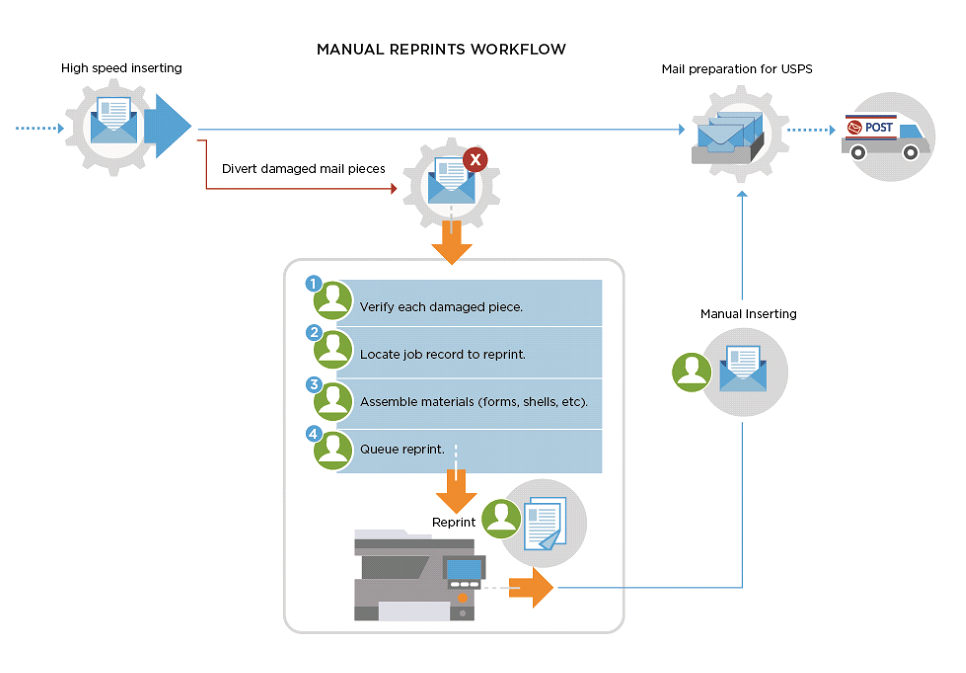

Here’s a quick look at the manual reprint process:

— A damaged mail piece is diverted and verified

— Time is then taken to look up which job the mail piece came from

— Next it is determined if the mail piece goes to reprint printer or the larger process printer

— Correct paper stock and pre-printed forms and shells are then located and assembled

— The reprint is then queued up on the correct printer

— Finally, the documents are manually inserted and reconciled

There are at least six manual steps per damaged document, which take operators away from optimizing the primary printing and inserting systems. It also requires maintaining sufficient stock of pre-printed cutsheet forms and shells. In fact, industry estimates suggest that materials and labor needed for manual reprints can cost anywhere between $15 to $20 per piece. And in today’s competitive transactional mail production market, every dollar counts.

Each of these manual steps in the reprint process also introduces risk. There is a higher chance of human errors such as insert, form or envelope mismatch, incorrect addressing, and lost mail pieces. If an envelope is opened or an a mail piece is shipped with any errors, there is a higher probability of privacy breaches. Any regulatory infringements or privacy violations can result in exposure to liability and fines.

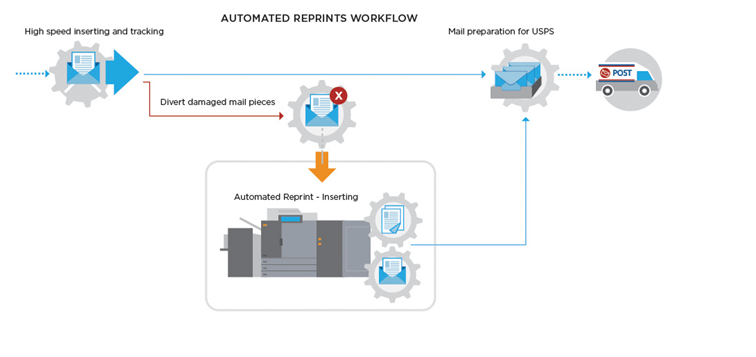

Fortunately, full-color automated reprints can solve many of these problems. This closed-loop system helps meet tight deadlines and regulated standards by increasing productivity and accuracy through a streamlined, highly-accurate automated process.

Documents from the printer are sent through high-speed finishing equipment, where mail pieces can be damaged or rejected. Data, which pinpoints damaged or missing mail pieces, is automatically sent via job-tracking software to a printer, which then reprints the missing mail inserts. A full color inkjet printer can even replicate the look of preprinted forms easily.

If you had a reprint inserter module, the reprints would automatically be inserted into a nearly identical envelope. Otherwise, the cutsheets could be fed back to a high-speed inserter or manually inserted. The mail pieces would then be reconciled with their original job. Additionally, the reports would be generated for proof of completing the entire job.

This simplified and data-driven process drives down costs by implementing plain paper factory initiatives and reducing labor needs. Improved quality and accuracy eases worries of regulation infringement. If you haven’t already done so, consider implementing an automated reprint solution in your operations.

Nicole Scott is a solutions marketing manager at Bell and Howell in Durham, North Carolina. Contact her at nicole.scott@bhemail.com.